2021 FDA Science Forum

Metal Implants and Immune Response: Characterization of Burst Nickel Release from Nitinol

- Authors:

- Center:

-

Contributing OfficeCenter for Devices and Radiological Health

Abstract

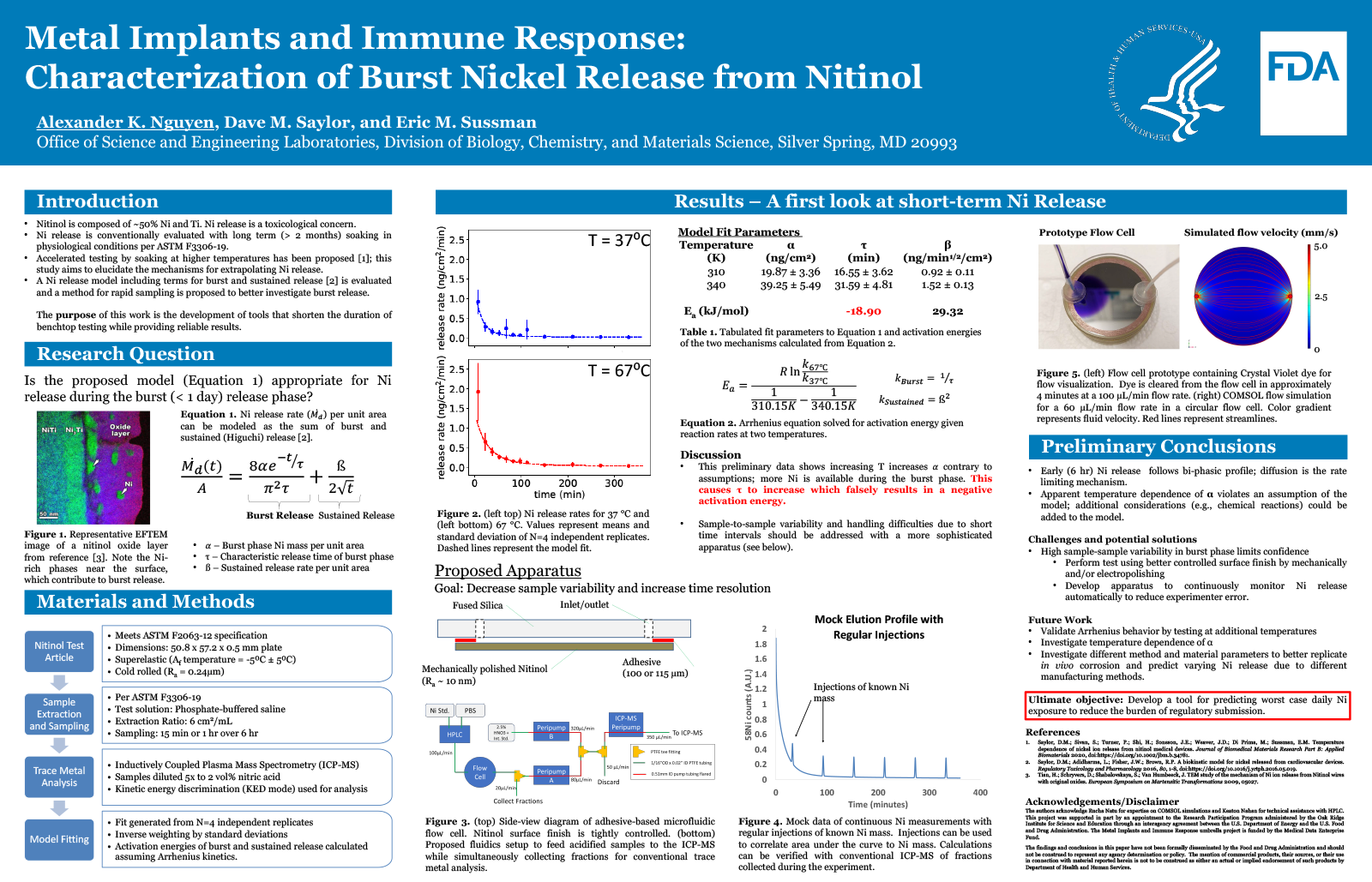

Nickel (Ni) exposure to the human body is a concern due to potential adverse effects that include hypersensitivity, systemic toxicity, and carcinogenicity. However, Ni-containing alloys such as 316LVM stainless steel, MP35N cobalt chrome, and nitinol are widespread in medical devices and are useful for the unique materials properties they offer. Nitinol, for example, has pseudoelastic or shape memory characteristics and can be found in many devices such as cardiovascular stents, orthodontic wire, and orthopedic implants. ASTM F3306-19 is a standard test method that can be used to estimate Ni exposure to inform toxicological risk assessments of Ni-containing alloys. In this method, one measures Ni release after multiple time points of soaking a sample in a physiologically relevant fluid such as phosphate-buffered saline (PBS). Ni release is typically measured over multiple months, but the highest Ni release rate is routinely observed within the first day or week. Due to the long test duration, sampling timepoints are typically infrequent; the highest sampling frequency in a recent review of this test method was once-daily during the first week. In addition, accelerated (higher temperature) test methods are attractive to reduce the time required to complete the test, but requires modeling the relationship between temperature and Ni release. This project aims to elucidate the effect of temperature on Ni release from nitinol within the first 24 hours of soaking. Nitinol plates were soaked at an extraction ratio of 1.0 cm2/mL in PBS heated to 37, 50, or 70 ⁰C with regular sampling intervals over 24 hr. Ni concentration in each sample was measured using inductively coupled plasma mass spectrometry and the Ni release rate profile generated for each soak temperature. The results from this study could guide the development of ASTM F3306 including recommendations for extraction ratios, temperature, and sampling frequency. Finally, improved understanding of the release kinetics could reduce regulatory burden by making validated accelerated test methods available or shortening the test duration for device safety assessment.