2021 FDA Science Forum

Development and Utilization of Process Modeling and Simulations for Supporting Quality Risk Assessment and Control of Continuous Pharmaceutical Manufacturing

- Authors:

- Center:

-

Contributing OfficeCenter for Drug Evaluation and Research

Abstract

Background

Continuous manufacturing (CM) is an emerging technology that offers several advantages over the traditional batch processes, including production rate flexibility, robustness, and product quality. Quality risk management is a broad system of considerations and practices, applied across the drug product lifecycle, that encompass the assessment, control, and communication of risks to product quality.

Purpose and Method

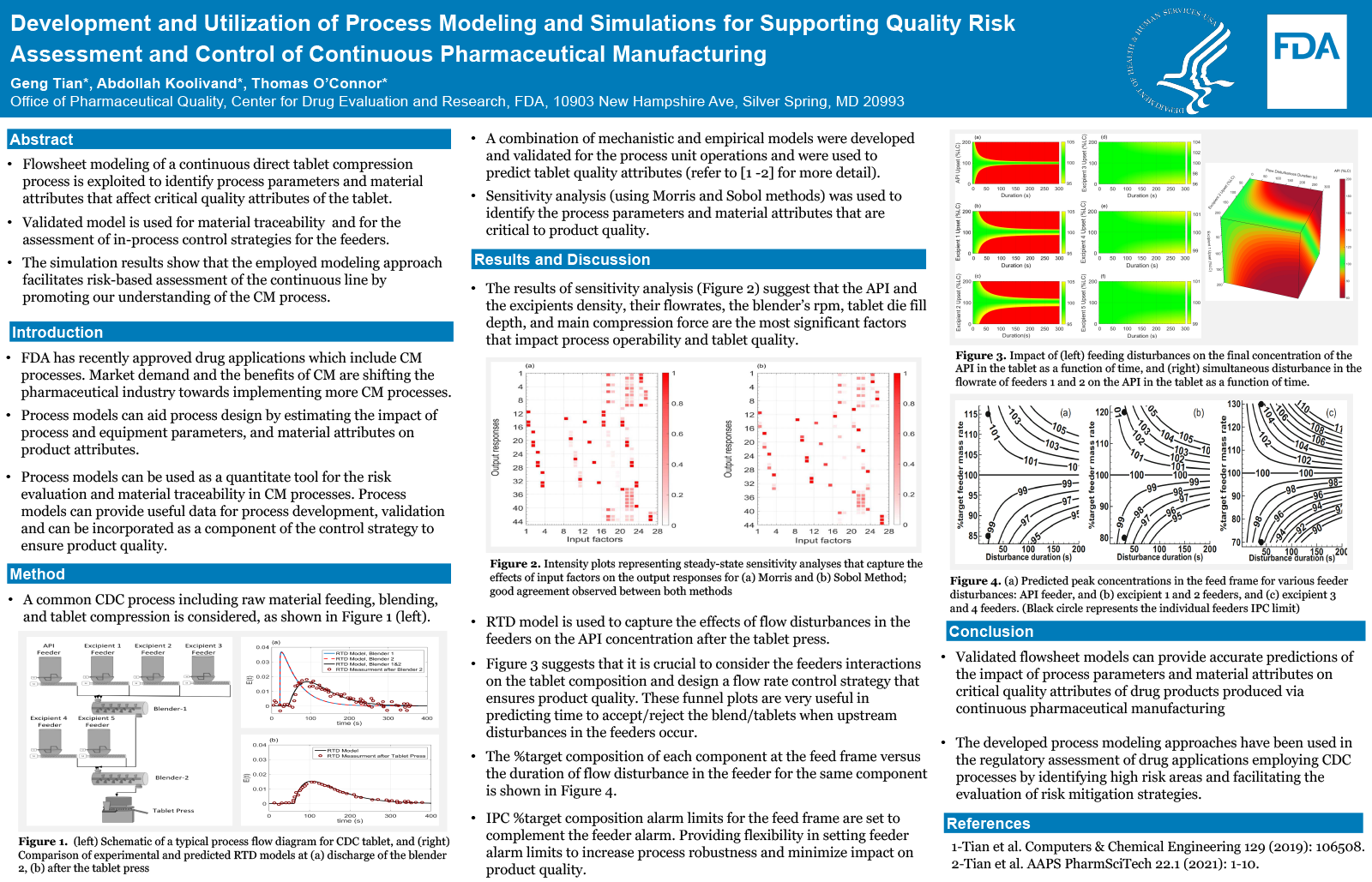

Various types of models can be used to support quality risk management, from qualitative models that elicit trends between process parameters and quality attributes of the drug product to quantitative models that can be used to proactively adjust the process in response to the occurrence of a process disturbance. In many cases, process models can aid process design by estimating the impact of process and equipment parameters, and material attributes on product attributes thereby providing a quantitative framework for assessing risk and evaluating risk mitigation approaches. In this work, we develop and validate process models for continuous direct compression (CDC) process and demonstrate how these process models can aid the risk assessment process through sensitivity analysis and the assessment of risk mitigation strategies through residence time distribution (RTD) analysis. Specifically, sensitivity analysis is used to rank the relative effect of the uncertain inputs on model outputs and identify the process parameters and material attributes that are critical to product quality. RTD analysis is used to examine a process�s ability to mitigate the risk of upstream disturbances (i.e., variation in the feeder's flowrate) on product quality.

Results and Conclusion

The results of sensitivity analysis suggest that the API and the excipients density, their flowrates, the blender's rpm, tablet die fill depth, and main compression force are the most significant factors that highly affect the process operability and tablet quality. In addition, our validated RTD model served as a tool for material traceability throughout the manufacturing line and facilitated setting the in-process control limits for the final blend composition. The developed process modeling approaches have been used in the regulatory assessment of drug applications employing CDC processes by identifying high risk areas and facilitating the evaluation of risk mitigation strategies.