DAIRY PRODUCT MANUFACTURERS-ATTACHMENT 1-4

H.T.S.T. FLOWCHART AND CHECKLIST

H.T.S.T. FLOWCHART

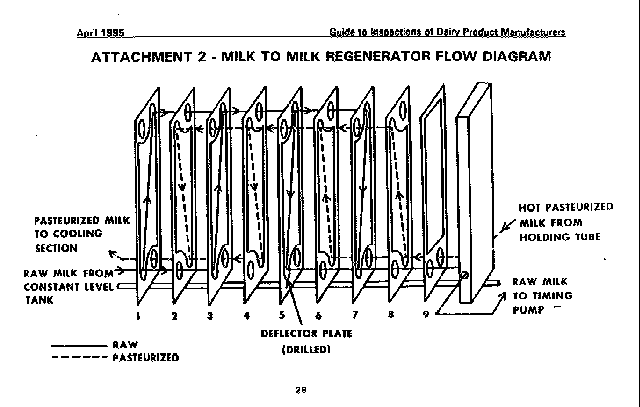

ATTACHMENT 2 - MILK TO MILK REGENERATOR FLOW DIAGRAM

SUMMARY OF SPECIFICATIONS FOR STANDARDIZED CHEESE

AND CHEESE PRODUCTS

Asiago - Cold-pack - page 29

Cook cheeses to Grated cheeses - page 30

Grated American cheese food-Sap sagago cheese -page 31

Skim milk cheese for manufaturing- Part-skim spiced cheese -page 32

Pasteurized process cheese to Pasteurized process pimento cheese - page 33

Pasteurized blended cheese to Pasteurized process cheese spread - page 34

Pasteurized process cheese spred with fruits etc. to end -page 35

PASTEURIZER CHART FOR FLUID MILK AND

OTHER DAIRY PRODUCTS

"Pasteurized" when used to describe a dairy product means that every particle of such product shall have been heated in properly operated equipment to one of the temperatures specified in the table of this paragraph and held continuously at or above the temperature for the specified time (or other time/temperature relationship which has been demonstrated to be equivalent thereto in microbial destruction). Minimum pasteurization times and temperatures for milk and milk products are:

| PRODUCT | TEMPERATURE | TIME |

|---|---|---|

| Milk and lowfat milks and non-fat milk (uncondensed). 890C (1910F) 1 second | 630C (1450F) 720C (1610F) | 30 minutes 15 seconds |

| 900C (1940F) 0.5 second 40C (2010F) 0.1 second 960C (2040F) 0.05 second 1000C (2120F) 0.01 second | ||

| Milk Products containing 10% milk products with sweeteners and condensed milk, condensed whey and similar products. | 660C (1500F) 750C (1660F) 890C (1910F) 900C (1940F) 940C (2010F) 1000C (2120F) | 30 minutes 15 seconds 1 second 0.5 second 0.1 second 0.05 second 0.01 second |

| Frozen dessert mixes, eggnog and products of similar viscosity. | 690C (1550F) 800C (1750F) 830C (1800F) 890C (1910F) 900C (1940F) 940C (2010F) 960C (2040F) 1000C (2120F) | 30 minutes 25 seconds 15 seconds 1 second 0.5 second 0.1 second 0.05 second 0.01 second |

Note: It is recommended that the minimum pasteurization time/temperature combinations be exceeded where possible.

Return to: Page Top | Inspection Start